Bomba de tubería de gran desplazamiento

Basándose en la especificación API 11AX, GB / T 18607 para bombas de pozos de petróleo y sus componentes, Sanjack ha desarrollado una serie de bombas de pozos de petróleo especiales adecuadas para diferentes condiciones de pozo. Estas bombas especiales para pozos de petróleo tienen una estructura novedosa, un rendimiento confiable, una eficiencia superior de la bomba y una larga vida útil, y se han utilizado ampliamente en varios campos petroleros.

Nota: si nuestro cliente necesita diferentes especificaciones y modelos de bomba de pozo de petróleo especial, también podemos diseñar y fabricar de acuerdo con los parámetros y requisitos proporcionados por el cliente.

Su Premier

Bomba de fondo de pozo para recuperación de petróleo pesado Fabricantes y proveedores

Bomba de desplazamiento grande

Diámetro de la bomba de 120,65 mm, carrera máxima de 9,2 my una producción de líquido diaria de 151-452m3

Gran diámetro de bomba

Sanjack suministró Weatherford con cilindros de bomba de 146 mm

Material de aleación de titanio

Bola de aleación de titanio y asiento de válvula de aleación dura, alta dureza, resistencia al desgaste y fuerte resistencia a la corrosión

Recuperación de petróleo de doble capa.

Se utiliza una estructura especial para completar las dos acciones de succión y descarga de aceite en un movimiento alternativo.

- Producción máxima diaria:t: 452m

- Resistencia al desgaste y resistencia a la corrosión

- Recuperación de petroleo de doble capa

- Alta producción de fluidos

- Recuperación de petroleo de doble capa

- No interferencia mutua

- Tres cámaras selladas

- Ahorre energía enormemente.

El taller de bomba insertible Sanjack se estableció en 1964, que tiene más de 50 años de historia. Tenemos una rica experiencia en producción y una gran capacidad en investigación y desarrollo. Nuestros productos incluyen varias series de bombas de tubería, bombas de varilla y bombas de varilla de bombeo especiales. Obtuvimos 32 patentes de tecnología nacional en la bomba de fondo de pozo. El taller de mecanizado para bomba insertible está equipado con más de 200 unidades de equipos, incluidos tornos CNC, fresadoras, rectificadoras, etc. El taller de galvanoplastia de bomba inserto cuenta con equipos avanzados de cromado en todo el país para barriles de bombas de pozo profundo. que puede procesar cilindros de bombas que van desde 1 1/4 pulg. (31,75 mm) a 5 3/4 pulg. (146,05 mm) y con una longitud de hasta 34 pies (10363 mm). El taller de ensamblaje de bomba inserto tiene máquinas de bruñido y dispositivos completos de prueba de presión de bombas y otros equipos. Las pruebas de rendimiento de sellado deben realizarse al 100% después de terminar el montaje de toda la bomba para garantizar plenamente la calidad de nuestras bomba insertible.

Send us your requirement, Let Sanjack support you

Large displacement tubing pump: The Complete Buying Guide for Importers and Buyers

Large displacement tubing pumps represent a small but significant part of the world of pumps, especially in oil and gas production.

These pumps can be categorized under a wide variety, depending on their working mechanism and specifications.

Although large displacement pumps were once the pillar of pumping different kinds of fluids, large centrifugal pumps are most-preferred for low pressure, high volume tasks.

This has left large displacement tubing pumps to handle more specific jobs, including the transfer of fluids in oil and gas wellbores.

This article is designed to briefly offer a guide into large displacement pumps, how they work, and how to buy the best varieties available.

In other words, this is a complete buying guide for large displacement tubing pumps. But first, let us look into large displacement tubing pump fundamentals.

Large displacement tubing pumps basics

Large displacement tubing pumps are often driven through positive displacement.

This type of displacement happens when a variable-volume cavity sucks an intake line to draw in the amount of fluid and reduce the volume of the cavity to discharge the fluid forcefully.

Once the liquid is sucked into the cavity, the inlet hose is blocked to prevent backflow.

Fluid backflow can be controlled using valves or by forcing the fluid past the intake and decreasing the volume of the pump’s chamber.

Accordingly, the discharge must be blocked before the next intake.

Large displacement pumps generate high pressures because they can work on a single, isolated volume.

Accordingly, these pumps can move thick fluids and deliver precise volumes.

And what is more impressive is the fact that large-displacement tubing pumps are more effective, highly mechanically complex, and costly compared to centrifugal pumps.

Why should you buy large displacement tubing pumps?

The decision to buy a large displacement pump should be preceded by choice for design and specifications. In that respect, it is worth noting that large-displacement tubing pumps can;

- Dispense precise volume of fluids, especially large displacement gas pumps.

- Achieve high pressure and low flow streams.

- Discharge viscous fluids, large displacement oil pumps

- Produce variable output rates in hydraulic systems, exceptionally large displacement axial piston pumps.

- Pump fluids with large solids without damaging the pumping system.

- Large displacement peristaltic pumps can isolate media and pump mechanisms without seals.

- These and other applications make large displacement pumps necessary and handy tools that you should have in when working on wellbores for oil and gas production.

Different ranges of large displacement tubing pump you need to check out

Large displacement pumps can be categorized according to their applications and designs.

This statement means that we have more than one large displacement tubing pump variety.

This section will take you through different varieties of large displacement tubing pumps, their applications, and possibly their advantages and disadvantages.

The working mechanism

The workover process of any large displacement pump is as follows:

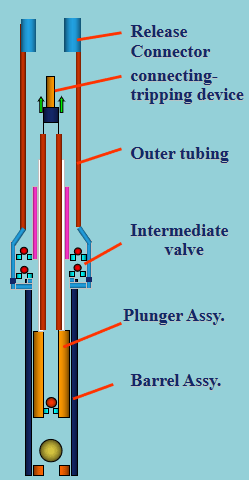

- The barrel is connected to the tubing and run directly into oil and gas wellbores up to the desired depth.

- The plunger is then put into the barrel with a sucker rod.

In any given case, the applicable tubing pump is often more massive than the rod pump in the same tubing. Large tubing pumps are designed with a simple structure, which makes the displacement bigger and suitable for shallow wellbores with high oil and gas production.

Types of large displacement tubing pumps

When you want to buy large displacement tubing pumps, it is essential to know the different ranges and their applications.

This information will help you understand a pump that is most suitable for your applications. These are some of the best large displacement tubing pumps that you can opt for to get the job done.

- THD, THC, and THM sucker rod and tubing pumps

The THD sucker rod pump is designed with a standing valve that is connected to the barrel directly and cannot be removed or pulled up separate from the barrel.

On the other hand, the THC or THM sucker rod pumps are designed with a standing valve that can be pulled separately from the barrel.

In a THC pump, the seating assembly is cup type, while the THM pump has a mechanical type seating assembly. These pumps are mostly suitable for frequent workover wellbores.

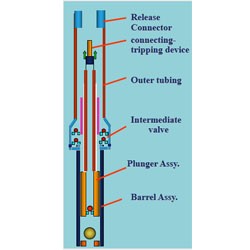

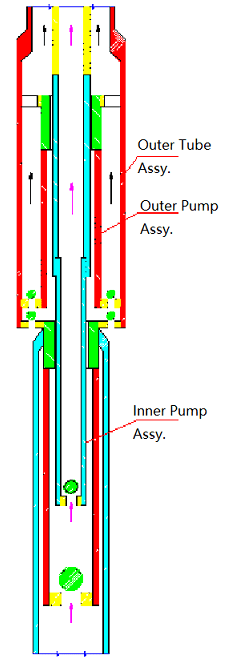

- Double-action sucker rod pump

A double-action sucker rod pump comes with a barrel comprising of a lower standing valve.

The barrel is then connected to a pipe string with the help of a sub.

The sub comes together with an upper standing valve, traveling valve, and hollow plunger all arranged in the barrel to form an under plunger and above the plunger. These plungers can move reciprocally.

At the same time, the double-action sucker rod pump has a hollow rod with a lower traveling valve.

The barrel is designed in a stepped manner, with the lower step having a larger diameter compared to the upper step.

The lateral wall of the plunger is made to have a through-hole just above the lower traveling valve.

This design is meant to facilitate interconnection between the plunger cavity and the chamber forming, especially when the plunger makes the downward movement in the lower step of the barrel.

As you can imagine, one of the disadvantages of the double-action sucker rod pump is that it is very complex in design and application.

Additionally, these pumps are quite costly due to the requirement of round-trips necessitated by the simultaneous lowering of the pipe string.

In other cases, double-action sucker rod pumps are associated with low efficiency caused by high resistance in the upper traveling valve.

All these drawbacks mean that double-action sucker rod pumps are not suitable for mixed fluids.

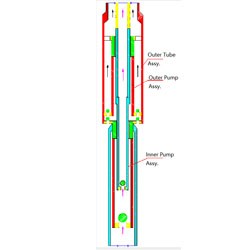

Dual-Channel oil well pump

The dual-channel oil well pump is a subsurface drive for a reciprocating piston pump used in oil and gas wellbores.

The working mechanism of this pump is designed that it is lifted mechanically out of the well.

Alternatively, they can use pressure in the bottom hole to help the fluid to flow to the surface.

This kind of arrangement is mostly used for onshore oil and gas production.

Depending on the size of the pump you are using, dual-channel oil well pumps are designed to produce between 5 and 40 liters of fluid with each stroke.

In most cases, the liquid is always an emulsion of water and crude oil.

The depth and weight of oil that need pumping determines the size of the pump you should buy.

Deeper extractions mean you need to go for more power to move the discharge column.

Beam-type dual-channel oil well pumps convert the rotary motion of the motor into a vertical reciprocating motion that is required to drive the polished rod and the sucker rod column load.

This working mechanism is known as the walking beam.

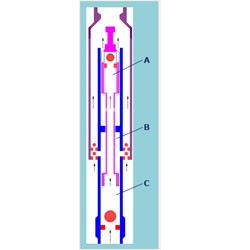

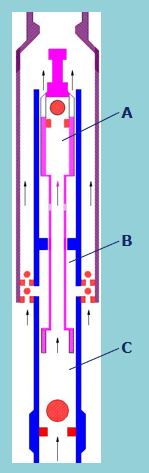

Triple action sucker rod pump

Triple action sucker rod pumps are made as a series of three sucker rod pumps, a lower valve, and a packer.

This pump uses gravity separation of oil and water to inject water into the injection zone downhole to reduce the ratio of water in the fluid.

This working mechanism helps to reduce the cost of production, protect the environment, and increase the rate of production.

The tripe action sucker rod pump can achieve a higher fluid injection pressure compared to a double-action sucker rod pump.

Specifications of large displacement pumps

The following table provides essential information about the specifications of large displacement pumps you should know before buying.

| Range | Nominal Diameter mm(in). | Plunger Length m(ft) | Stroke m | Pump Constant m3/d | Tubing And Thread | Sucker Rod

In |

| 20-125TH | 32(1.25) | 1.2-1.8

(4-6) |

0.6-7.3 | 1.14 | 2⅜NU/EU | ¾ |

| 25-125TH | 32(1.25) | 0.6-7.3 | 1.14 | 2⅞NU/EU | ¾ | |

| 20-150TH | 38(1.50) | 0.6-7.3 | 1.64 | 2⅜NU/EU | ¾ | |

| 25-150TH | 38(1.50) | 0.6-7.3 | 1.64 | 2⅞NU/EU | ¾ | |

| 20-175TH | 44(1.75) | 0.6-7.3 | 2.24 | 2⅜NU/EU | ¾ | |

| 25-175TH | 44(1.75) | 0.6-7.3 | 2.24 | 2⅞NU/EU | ¾ | |

| 25-225TH | 57(2.25) | 0.6-7.3 | 3.69 | 2⅞NU/EU | ¾ | |

| 30-275TH | 70(2.75) | 0.6-7.3 | 5.50 | 3½NU/EU | ⅞ | |

| 35-325TH | 83(3.25) | 0.6-7.3 | 7.70 | 4NU/EU | ⅞ | |

| 40-375TH | 95(3.75) | 0.6-7.3 | 10.26 | 4½NU/EU | 1 |

What to look out for when buying large displacement pumps

Once you understand the specifications listed in the table above, you should know how to quote your order when buying large displacement tubing pumps.

For instance, when placing your order, you should ensure that you specify the full designation of the large displacement tubing pump.

The designation includes:

- tubing size

- pump bore

- types of pump

- barrel thickness

- location and type of seating assembly

- barrel, plunger and extensions length

Additionally, you must ensure you specify:

barrel and plunger material

plunger clearance(fit)

design version and materials of valves

Other pumps you can consider for upstream oil wellbores

Both large displacement and centrifugal pumps are essential in the oil and gas industry.

The pumps are often used as part of tri-phase pumping applications in which more than one type of the pumps are used to accommodate all fluids to reduce the general cost of the equipment, make installations more straightforward, improve production, and smaller footprint.

Other large displacement pumps used in the oil and gas industry

- Large progressive cavity pumps

These pumps are sometimes called the eccentric screw pumps or the single screw pumps.

They can pump difficult fluids and are most preferred for pumping viscous fluids or liquids with solids and debris.

These pumps work by using a single rotor or screw found inside a double-threaded rubber stator to generate the pressure necessary for pumping fluids.

This type of pump may be perfect for you if you are working in shallow wells or at the surface.

- Large twin screw pumps

This type of pump works by rotating and forming chambers with the intermeshing of two screws found inside the housing.

This movement generates a pressure difference once the chamber is full of fluids.

The fluid is then forced to the discharge end at high pressure. The pumping process in some large twin screw pumps can be reversed.

Large twin screw pumps can handle almost all non-homogeneous fluids with any lubricity, viscosity, and abrasiveness.

These pumps are suitable for use in applications that contain high gas volume fractions and varying inlet conditions.

Apart from centrifugal and displacement pumps, you can also go for other types of pumps for the oil and gas industry.

As much as they are not common, these pumps also offer practical solutions to your pumping applications.

Let us take a look at some examples below.

- Large Deep Well Submersible Pumps

Just like the name suggests, large deep well submersible pumps are submerged in deep waters to perform various upstream processes.

Each unit is often oil-filled for reliability and long-lasting solutions while also reducing the overall cost of operation in the life cycle of the pump.

These pumps work with heavy-duty impellers, dual bearings, and various seal options.

Additionally, large deep well submersible pumps can pump up to 6,000 cubed meters, heads to 800 meters, and speeds up to 3,600 rpm.

- Large chemical Process Pumps

Large chemical process pumps are used to handle hazardous chemicals in various industrial applications, including upstream oil and gas tasks.

These pumps can move harmful or corrosive chemicals efficiently while avoiding any form of damage on equipment or personnel that occur at the workplace.

Large chemical process pumps use both close coupling, heavy-duty casing, sealed chamber, specialty impellers, and other pumping mechanisms to move hazardous chemicals.

- Large oil Skimmer Aluminum Lobe Pumps

These are rotary lobe pumps that are mostly used upstream, midstream, and downstream in the oil and gas industry.

Large oil skimmer aluminum lobe pumps are often light-weight with large flow range, dry run abilities, compact, and move highly viscous fluids.

- Large Multiple Screw Pumps

Large multiple screw pumps are the newest inclusion in the world of pumps, and they come in a wide variety including double, geared-twin, and triple screw pumps.

Large multiple screw pumps offer ranges to 2500 GPM / 1160 psi. Additionally, these pumps can handle both high and low viscosity, lubricating and non-lubricating fluids.

These are some of the pumps you can consider when shopping for large displacement pumps for the oil and gas industry or their alternatives.

The bottom line

This article has demonstrated that large displacement tubing pumps share some specifications and, in some cases, differ significantly.

Similar pump technology and designs may be used across many industries requiring different precision, conditions, changeover, and handling.

Large displacement pump manufacturers often specialize in one range of pumps, making it an uphill task to compare technologies among different distributors.

We hope that this article at least points you in the right direction, especially onto various varieties and working mechanisms of large displacement tubing pumps.