Bomba de fondo de pozo para recuperación de petróleo pesado

- 40 años de experiencia en el diseño y fabricación de bombas de subsuelo

- Participó en la elaboración de la norma nacional de bomba de subsuelo

- 20 años de experiencia en la fabricación de bombas de varilla API11AX

Su Premier

Bomba de fondo de pozo para recuperación de petróleo pesado Fabricantes y proveedores

Certificación API 11AX

En 2001, SanJack obtuvo con éxito el certificado API 11AX y comenzó a exportar bombas de subsuelo al extranjero.

Alta viscosidad

La bomba de subsuelo se puede utilizar para la recuperación térmica de petróleo superpesado. Viscosidad del aceite: más de 50000 mPa.s

Recuperación en frío y recuperación térmica

La bomba de subsuelo es adecuada para la recuperación térmica de petróleo pesado y la recuperación de petróleo convencional.

Producción de petróleo de pozos desviados

La bomba de subsuelo se puede utilizar en pozos que tienen un grado de inclinación inferior a 40 °

- Viscosidad del petróleo crudo dentro de 4000mpa.s

- Relación gas-aceite inferior a 800.

- Inyección de vapor para recuperación térmica

- Evita la caída de objetos.

- Viscosidad <4000mPa.s, recuperación en frío

- Corte de arena <0,1%, recuperación térmica.

- Petróleo pesado y petróleo superpesado

- Control de arena

- Pozos de petróleo pesado de alta viscosidad

- La producción en frío convencional no funciona

- Inyección y producción integradas

- Anti incrustaciones

- Recuperación de petróleo de calefacción por cable

- Estructura hueca

- Heredar múltiples funciones

- Apertura y cierre forzados

El taller de bomba inserto Sanjack se estableció en 1964, que tiene más de 50 años de historia. Tenemos una rica experiencia en producción y una gran capacidad en investigación y desarrollo. Nuestros productos incluyen varias series de bombas de tubería, bombas de varilla y bomba inserto especiales. Obtuvimos 32 patentes de tecnología nacional en la bomba de fondo de pozo. Estos productos se han exportado a SHELL, CHEVRON, GE, SCHLUMBERGER, NOV, JOHN CRANE, CAMERON, KBM, etc. Nuestra capacidad de producción anual es de 15.000 unidades

Send us your requirement, Let Sanjack support you

Heavy Oil Recovery Downhole Pumps: The Complete Buying Guide for Importers and Buyers

The geological features of oil and gas wells, coupled with heavy oil immobility, make the recovery process in wellbores a challenge. Recently, there have been developments in commercial heavy oil recovery downhole pumps and improved drainage areas in shallow reservoirs.

Other recovery methods have been developed, for instance, downhole technologies with cold and thermal production.

In most cases, artificial lifts have been used in situations where the wells cannot offload naturally at an economical rate.

When talking about artificial lifts, we include all heavy oil reservoirs that require heavy oil recovery downhole pumps to transfer highly viscous fluids at low-pressure conditions.

The heavy oil production sometimes comes with associated water from the reservoir to create emulsions, leading to high loads on artificial lifts and higher consumption of power and costly chemicals.

The development of heavy oil recovery pumps depends on the optimization and selection of handling viscous fluids.

This article reviews some of the best heavy oil recovery pumps and pumping systems performance.

If you are looking to buy heavy oil recovery downhole pumps and have no clue where to get started, here is an article that will point you in the right direction.

Types of Heavy Oil Recovery Pumps

Heavy oil recovery downhole pumps can be categorized into different types, depending on their working mechanisms and applications in oil and gas wells.

Therefore, you need to know how you can identify the most suitable type of heavy oil recovery downhole pump for your applications.

Here are some of the best heavy oil recovery downhole pumps you may want to look at to get you started.

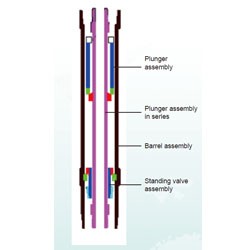

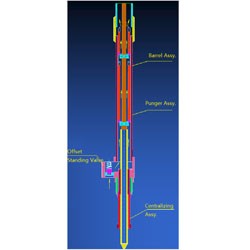

1.Double-plunger valve downhole pump

Plunger pumps are categorized under reciprocating positive displacement pumps designed to use pistons to transfer fluids through a cylindrical chamber.

These pumps are sometimes known as service pumps or high viscosity oil well pumps due to their ability to deliver high pump pressure and handle viscous fluids.

Working mechanism

Double-plunger valve downhole pumps are positive displacement pumps. This means they work on contraction and expansion in the pump cavity to transfer fluids. To be more specific, these are reciprocating pumps with cavities that expand and contract in reciprocating motions.

Double plunger valve pumps for downhole applications use a rotational mechanism to create a reciprocating motion along the axis.

This motion creates pressure build-up in the cylinder or the barrel, forcing fluids through the pump.

The pressure in the pump chamber triggers the valves at the suction and discharge ends.

Features

- The traveling valve in these pumps adopts a mechanical valve structure to open and close with the sucker rod moving up and down.

- The sealing function in a double-plunger valve downhole pump is separated from the plunger’s stress to extend the lifespan of the pump

- The plunger of this pump has a floating structure designed with a self-repair function that extends the valves’ life span

Applications

- The double-plunger valve pump for downhole applications can achieve cold production at 50 ℃ and crude oil viscosity within 4000mpa.s.

- This heavy oil recovery downhole pump is suitable for wellbores with a gas-oil ratio lower than 800.

- The double-plunger valve downhole pump can work correctly in wells that slant at less than 40°.

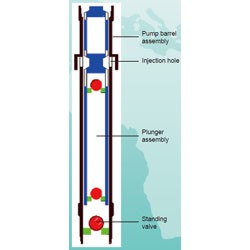

2.Double Plunger Injection-Production Oil Well Pump

Also known as the sucker-rod injection production pump, the double plunger injection-production pump comes with a conventional beam pumping unit, a production pump, sealed piston, bridge packer, injection pump, and oil-water separation system.

Working mechanism

When the oil goes into settling cup of oil-water separator, the fluid produced is divided into two layers due to gravity.

This means water has a higher density while oil with low water cut has low density.

The layer of water, which is the lowest, flows through the central pipe in the oil-water separator to the injection pump’s suction end.

This water circulates back into the injected layer as the upper layer of oil goes through the central channel to the suction port and the surface.

Features

The downhole pump is designed with fluid column positioning and separated into the oil portion and water portion.

This feature helps the pump lift oil to the surface while injecting water into the injection zone selectively. Accordingly, the double plunger injection-production pump has the following specifications.

- A housing with top and bottom walls defining the cylinder or barrel

- A reciprocating plunger that is located within the barrel and through induction and production strokes

- A movable piston is positioned between the plunger and the top wall to separate the oil chamber from the water injection zone.

- An oil intake assembly supports a one-way flow of fluids from the fluid column to the oil chamber.

- An oil exhaust that helps in one-way transfer of fluids from the oil chamber to the surface

- Water intake with flow restriction position balances the pressure drop in the oil intake assembly while allowing a one-way flow of fluids from the fluid chamber to the water chamber.

- A water discharge to allow one-way fluid flow from the water chamber into the injection zone.

In one induction stroke, oil flows into the oil chamber while the water goes into the water chamber at a given oil to water ratio.

On the other hand, the production stroke forces oil to the surface and water into the injection zone as long as the injection zone pressure is overcome.

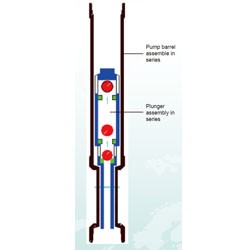

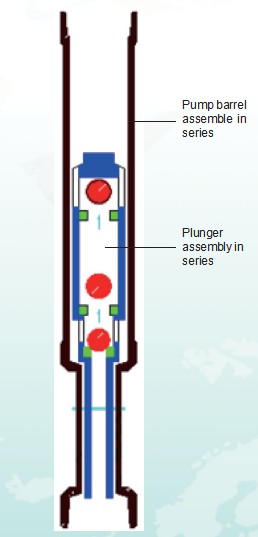

3.Hydraulic Feedback Sucker Rod Pump

The hydraulic feedback sucker rod pump is designed with two different pumps with different pump diameters.

These heavy oil recovery downhole pumps are often made for cold recovery of heavy oil with a viscosity of 4000mpas and below, thermal recovery of heavy oil with single well steam huff and puff, and oil wells with frequent fracture and low viscosity.

Hydraulic feedback sucker rod pumps that come with stainless steel valve covers and cemented carbide valve pair are suitable for corrosive wellbores or heavy oil wells with high salinity.

Working mechanism

Hydraulic feedback sucker rod pumps are designed with two different barrels connected with a plunger.

The pump forms the gas injection channels to start the injection process when the plunger is raised.

This action is in line with the hydraulic feedback principle.

When the plunger is lowered, the downward force reduces the friction between the viscous oil and sucker rod to prevent the sucker rod from falling.

Features

- The pump has a carbon steel barrel and plungers.

Main Parameters of the Hydraulic Feedback Sucker Rod Pump

- TYPE API SCP25-225/150TH API SCP30-275/175TH

- Nominal D(mm): 57.2/38.1 69.6/44.5

- Plunger length(mm): 914/900

- Barrel Length(mm/in) 3300-4500

- The thread of upper pipe 2 7/8 3 1/2

- The thread of downpipe 2 7/8 2 7/8

- The thread of sucker rod 3 /4 7/8

- Max OD (mm) 89.5 107

- Max available depth 2000 1600

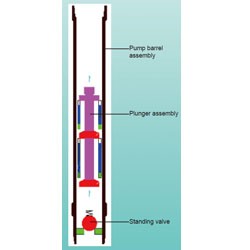

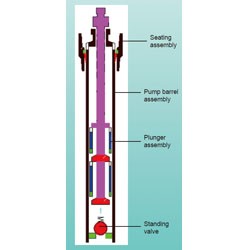

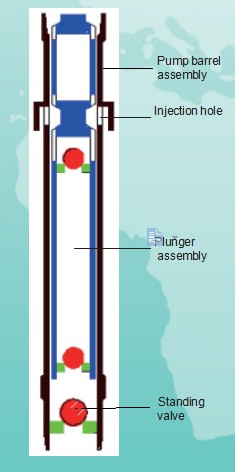

4.Mechanical Top Seal Rod Pump

The mechanical top seal rod pump is designed according to a single well steam injection technology requirements.

The same technology is used for steam injection thermal recovery of heavy oil and super heavy oil.

Mechanical addition to the pump prevents it from getting stuck due to the accumulation of solids around the hold-down.

Once the mechanical top seal rod pump is placed in its seating location, the sucker rods’ weight forces the rubber element outwards until it comes into contact with the tubing wall.

The pump can be easily retrieved by pulling the rod string to disengage the setting.

In case of any damage caused to the rubber element, it can be replaced without replacing the entire assembly.

Features

-

- The pump adopts the form of a top mechanical seal lock making it convenient and straightforward to operate.

- The plunger assembly of the mechanical top seal rod pump adopts a double plunger mechanical valve structure that facilitates the recovery of highly viscous oil.

- The standing valve is designed to adopt the spring forced reset structure to prevent the standing valve ball from closing the lag.

- The pump has a blocking valve that blocks sand to prevent sand accumulation in the barrel and the plunger.

Advantages of the mechanical top seal rod pump

- The design of this pump reduces its chances of being stuck.

- The build and structure of the mechanical top seal rod pump ensure no sand accumulation in the hold-down.

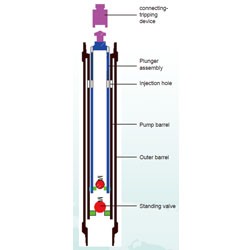

5.Cable through and heating insert pump

The cable through and heating insert pump is designed so that the cable through and heating pump can go through the pump to enhance electric heating or mix hot water.

Additionally, the pump can use viscosity reduction measures on the whole working wellbore section.

This pump employs the working mechanism that makes it suitable for oil production in heavy oil wells and in conditions that a traditional production mode is not possible.

Working mechanism

The connector arrangements in cable through and heating insert pumps are used to attach the electrical conductor cable to a mineral insulated resistance heater cable.

The connection helps to join one or more electrical conductors to a cold lead mineral insulated cable.

These connectors enable joining the MI heater cable and the ESP pump cable to the production tubing.

The pump is then lowered into the downhole oil well up to the desired depth and location.

Applications

cable through and heating insert pumps can be used to enhance oil production in many oilfield applications.

But to identify where and when these pumps can be used effectively, you need to understand how they work, their structure, and specifications.

One downhole heater comes with a single electrical conductor wire placed concentrically in a stainless steel metal tube.

An inert mineral insulation material like magnesium oxide is used to insulate the conductor from the outer tubing.

The downhole resistance heaters are, in most cases, joined to the production tubing with a power supply source from the surface.

In heavy oil wellbore, these pumps are submerged in the oil production zone to raise the oil’s temperature and make it less dense for efficient flow to the surface.

In gas wells, the pumps are used to heat the entire length of the production tubing to prevent scale formation, paraffin, and hydrates that may form in the tubing and block or limit gas flow.

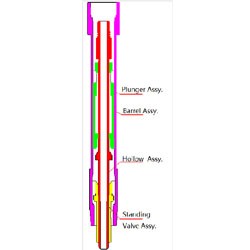

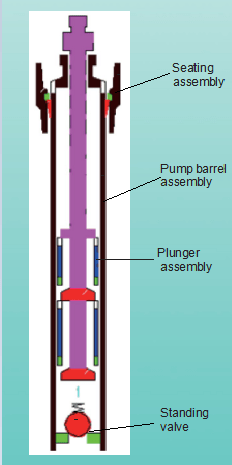

6.Super heavy oil injection and production pump

The production of heavy oil and the increasing water cut leads to potentially high emulsion viscosity.

When this is mixed with gas, the high viscosity comes with a challenging operating condition, especially for subsea pumps.

This condition calls for super heavy oil injection and production pumps.

Super heavy oil injection and production pumps are designed for thermal recovery of super heavy oil in single well steam huff and puff.

One string operation can overcome two steps in steam injection and oil production. This mechanism can be used with insulated tubing and hollow sucker rod to greater efficiency.

Application

The super heavy oil injection and production pump can be used for steam injection and oil recovery at the same time while also acting as an anti-scale.

This pump is specifically designed for single well steam injection recovery of heavy and super-heavy oil.

Lastly, the pump can be used with an insulated tubing and hollow sucker rod to improve its efficiency.

Factors to Consider When Buying Heavy Oil Recovery Pumps

Heavy oil recovery requires heavy oil recovery downhole pumps and super heavy oil injection pumps.

However, these pumps are made in a wide variety of sizes, designs, and working mechanisms.

Accordingly, heavy oil recovery downhole pumps come with different specifications that make them suitable for different heavy oil recovery and production applications.

Therefore, you need to understand what you need by evaluating certain aspects of the pump before buying.

This article is generally a buyers’ guide to heavy oil recover pumps.

The post has looked in detail into various types of heavy oil recovery downhole pumps.

The information given here is enough to help you make the best buying decision.

However, there are other factors that you need to look into to help you choose the best heavy oil recovery pump for downhole applications. Here are some:

- The condition of the oil well

- The structure of the pump

- The pumping mechanism

- The cost of the pump

You can contact Sanjack Petro for any heavy oil recovery pump today.

Happy shopping.